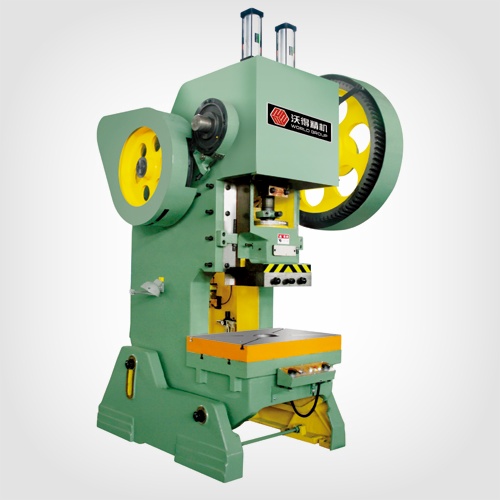

JH25 Series C-frame Two Points Press

Features: The JH25 C-frame double crank press is the commonly used product in blanking, piercing and cutting the larger piece of sheet metal. The worktable in large size is more suitable for the progressive dies working on different stations, which can greatly improve the production efficiency.

Description

The JH25 C-frame double crank press is the commonly used product in blanking, piercing and cutting the larger piece of sheet metal. The worktable in large size is more suitable for the progressive dies working on different stations, which can greatly improve the production efficiency.

Features:

- Welded body with steel plate and high intensity.

- Suitable for multiple dies automatic line and multi level dies continuous punching.

- Double crankshaft pitmen totally eliminating side forces by reverse rotation.

- Combined wet multi discs friction clutch and brake.

- Cluster gear adopts the flooding oil lubrication.

- Six-face rectangle lengthen guide.

- Adopts electric die height adjustment with digital display.

- Equipped with hydraulic overload protecting device.

Main Technical Specifications:

| Parameter | Unit | JH25-110 | JH25-160 | JH25-200 | |

| Nominal Capacity | KN | 1100 | 1600 | 2000 | |

| Nominal Stroke | mm | 5 | 6 | 7 | |

| Slide Stroke Length | mm | 180 | 200 | 250 | |

| Slide Strokes Per Minute | Fixed | times/min | 50 | 45 | 35 |

| Variable | times/min | 30-60 | 35-55 | 25-40 | |

| Max. Die Set Height | mm | 400 | 450 | 500 | |

| Die Height Adjustment | mm | 90 | 100 | 110 | |

| Throat Depth | mm | 350 | 390 | 430 | |

| Distance Between Uprights | mm | 1470 | 1600 | 1920 | |

| Bolster Size | F x B | mm | 680 | 760 | 840 |

| L x R | mm | 1880 | 2040 | 2420 | |

| Bolster Thickness | mm | 155 | 165 | 170 | |

| Slide Bottom Size | F x B | mm | 520 | 580 | 650 |

| L x R | mm | 1400 | 1500 | 1850 | |

| Bolster Surface Height | mm | 900 | 900 | 1000 | |

| Overall Size | F x B | mm | 1820 | 2080 | 2370 |

| L x R | mm | 1970 | 2150 | 2550 | |

| H | mm | 3200 | 3380 | 3820 | |

| Motor Power | Kw | 11 | 18.5 | 22 | |

| Weight(Approximate) | Kg | 14000 | 19000 | 26500 | |

| Press Pressure | Mpa | 0.5 | |||

| Parameter | Unit | JH25-250 | JH25-315 | |

| Nominal Capacity | KN | 2500 | 3150 | |

| Nominal Stroke | mm | 7 | 7 | |

| Slide Stroke Length | mm | 280 | 280 | |

| Slide Strokes Per Minute | Fixed | times/min | 30 | 30 |

| Variable | times/min | 20-35 | 20-35 | |

| Max. Die Set Height | mm | 550 | 550 | |

| Die Height Adjustment | mm | 120 | 120 | |

| Throat Depth | mm | 470 | 480 | |

| Distance Between Uprights | mm | 2190 | 2170 | |

| Bolster Size | F x B | mm | 920 | 940 |

| L x R | mm | 2700 | 2800 | |

| Bolster Thickness | mm | 180 | 190 | |

| Slide Bottom Size | F x B | mm | 700 | 700 |

| L x R | mm | 2100 | 2100 | |

| Bolster Surface Height | mm | 1100 | 1090 | |

| Overall Size | F x B | mm | 2850 | 2850 |

| L x R | mm | 2700 | 2700 | |

| H | mm | 4180 | 4180 | |

| Motor Power | Kw | 30 | 37 | |

| Weight(Approximate) | Kg | 35000 | 36000 | |

| Press Pressure | Mpa | 0.5 | ||

Standard Equipments:

- Wet clutch

- Hydraulic overload protecting pump

- Auto lubrication system

- Manual lubrication system

- Balance cylinders for slide and upper die

- Digital die height indicator

- Joint for miss-feeding

- Touch screen

- Electronic crankshaft angle indicator

- Cam controller

- Movable control panel

- Die height adjusted motor

- PLC

- Device for knockout

- Joint for air

- Foundation bolts

Optional Equipments:

- Light curtain

- Foot pedal

- Leather bag die cushion

- Die quick change device

- Auto feed shaft

- Inverter

- Absorbing pads